A bit of a longshot this, but what the hey...

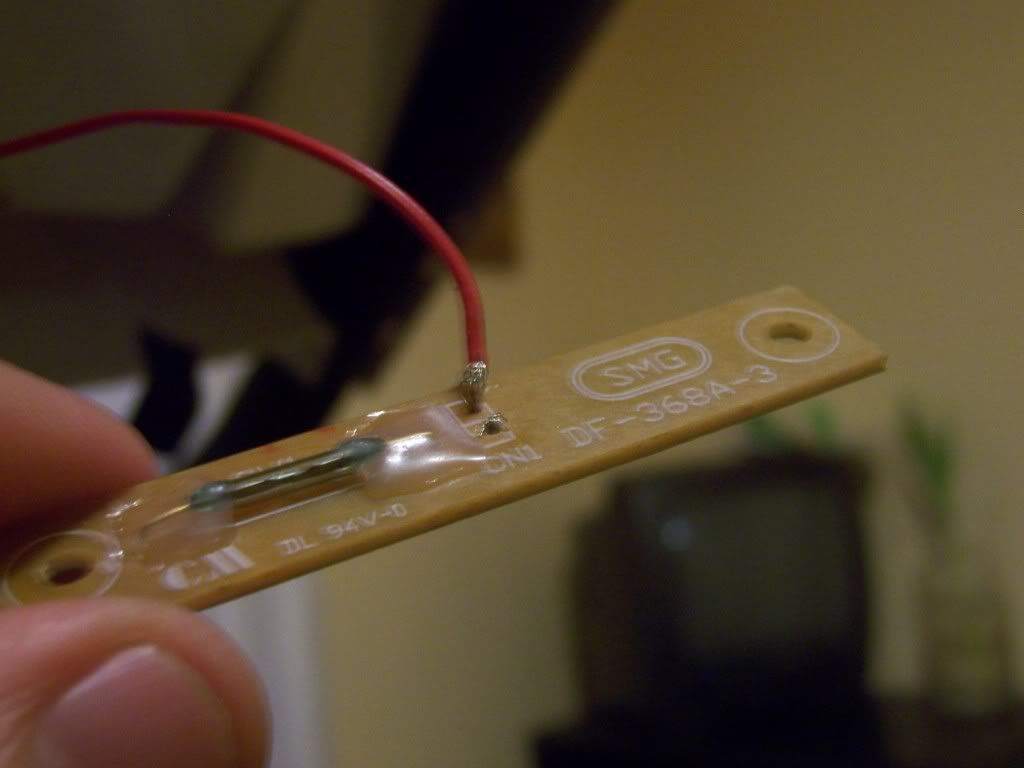

Much like the Rebel Alliance found the Death Star's one weakness, my 2 year old boy found the weakness of our treadmill, by yanking out the one exposed wire, and rendering it an expensive piece of furniture. Here's a picture...

As you can see, the red wire is just about still in place, but the black wire is gone. All that's left are a couple of tiny strands of wire above the writing CN1. Here's what the back of the board looks like.

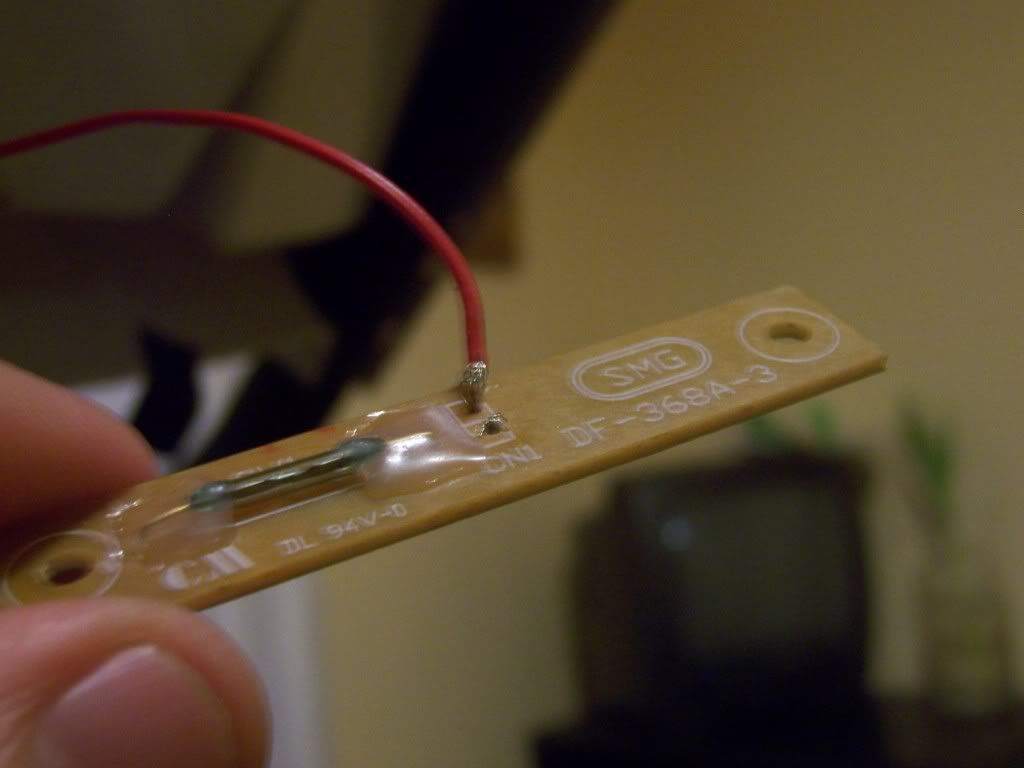

The two wires connect to the silver blobs to the left of the D. I presume that when they made it, they threaded the wires through the board and soldered them.

My problem is, how do I reconnect the black wire? I've tried to make as much contact as I can between the "stump" of wire on the board and the stripped black wire, then taping them down. No good. If I scrape off the silver blobs, will I just destroy it, or can I re-solder it back (bear in mind I've never soldered in my life)?

Any ideas whatsoever appreciated, because I'd like it to work again, and it's too big to fit in the bin.

Much like the Rebel Alliance found the Death Star's one weakness, my 2 year old boy found the weakness of our treadmill, by yanking out the one exposed wire, and rendering it an expensive piece of furniture. Here's a picture...

As you can see, the red wire is just about still in place, but the black wire is gone. All that's left are a couple of tiny strands of wire above the writing CN1. Here's what the back of the board looks like.

The two wires connect to the silver blobs to the left of the D. I presume that when they made it, they threaded the wires through the board and soldered them.

My problem is, how do I reconnect the black wire? I've tried to make as much contact as I can between the "stump" of wire on the board and the stripped black wire, then taping them down. No good. If I scrape off the silver blobs, will I just destroy it, or can I re-solder it back (bear in mind I've never soldered in my life)?

Any ideas whatsoever appreciated, because I'd like it to work again, and it's too big to fit in the bin.